Fishbowl warehouse management is revolutionizing how businesses handle their inventory, moving beyond traditional methods to offer unparalleled accuracy and visibility. This approach centers on a dynamic, interconnected system designed to streamline operations and enhance efficiency. We’ll delve into its core principles, the technologies that power it, and the significant benefits it brings to warehouse operations.

Understanding the intricacies of a fishbowl warehouse management system is crucial for any organization aiming to optimize its supply chain. This methodology provides a holistic view of inventory, ensuring that every item is accounted for from the moment it enters the warehouse until it leaves. By embracing this advanced system, businesses can anticipate a marked improvement in their inventory control, leading to better decision-making and a more agile operation.

Understanding the Core Principles of a Fishbowl Approach to Managing Warehouse Inventory.

The “fishbowl” concept in warehouse management refers to a methodology that emphasizes complete visibility and control over inventory, akin to observing every item within a transparent fishbowl. This approach moves away from siloed data and manual tracking, aiming to create a unified, real-time view of stock levels, movements, and statuses. At its heart, a fishbowl system is built on the principle that every item, from its arrival to its departure, should be meticulously tracked and accounted for within a central, accessible database.

This continuous flow of information allows for proactive decision-making, minimizing stockouts, reducing excess inventory, and optimizing operational efficiency. Unlike traditional methods that might rely on periodic cycle counts or separate spreadsheets for different inventory aspects, a fishbowl system integrates all facets of inventory management into a single, dynamic ecosystem. This interconnectedness is crucial for achieving high levels of inventory accuracy, as discrepancies are identified and resolved almost instantaneously rather than after significant accumulation.

The ultimate goal is to foster an environment where every stakeholder has the same, up-to-date information, thereby enhancing collaboration and reducing the guesswork inherent in less integrated systems.The operational flow of a fishbowl warehouse management system is characterized by a continuous cycle of receiving, put-away, picking, packing, and shipping, all underpinned by robust data capture and real-time updates. When goods arrive, they are immediately scanned and entered into the system, assigning them a unique identifier.

This could be a barcode, RFID tag, or serial number, depending on the sophistication of the setup. The system then guides the put-away process, directing warehouse personnel to the optimal storage location based on factors like item velocity, size, and compatibility with other stored goods. During picking, orders are generated electronically, and the system directs pickers along the most efficient routes within the warehouse, again minimizing travel time and errors.

As items are picked, their status is updated in real-time, reflecting their movement from storage to staging areas. The packing stage involves verifying picked items against the order, and upon completion, the system updates inventory levels to reflect items allocated to an order but not yet shipped. Finally, when an order is shipped, the inventory is officially deducted from stock, and relevant shipping documentation is generated.

This end-to-end tracking provides unparalleled visibility, allowing managers to see not just how much of an item they have, but also where it is, its status, and its history. This contrasts sharply with traditional methods where inventory counts might be static for periods, leading to inaccuracies when actual stock levels change due to sales, returns, or damage that hasn’t been recorded.

The advantages are manifold: significantly improved inventory accuracy, reduced carrying costs through better stock management, enhanced order fulfillment rates, and a proactive approach to identifying and mitigating potential supply chain disruptions.

Key Components and Technologies of a Fishbowl Warehouse Management Solution.

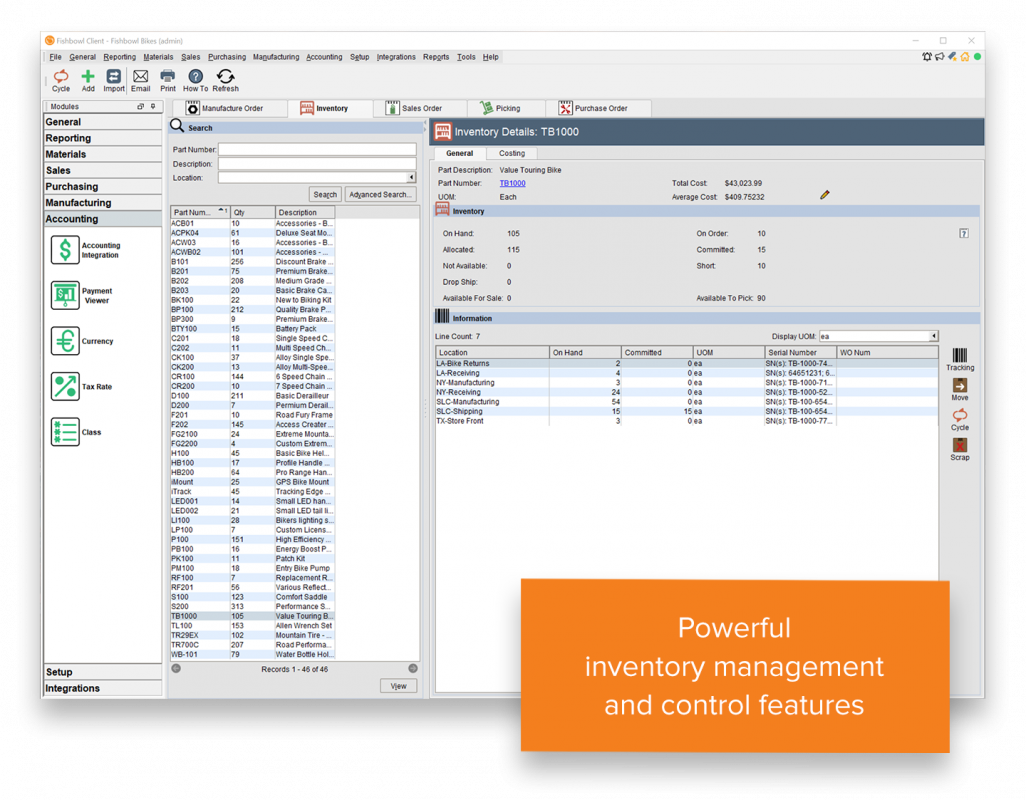

A robust fishbowl warehouse management solution is typically composed of several interconnected key components and technologies that work in concert to achieve comprehensive inventory control and visibility. At the core is the Warehouse Management System (WMS) software itself. This is the central brain, a sophisticated application designed to manage all warehouse operations from receiving to shipping. It typically includes modules for inventory tracking, order management, receiving, put-away, picking, packing, shipping, and reporting.

The WMS acts as the single source of truth for all inventory data. Crucial to the WMS are barcode or RFID scanning technologies. Barcodes, read by handheld scanners or fixed scanners on conveyor belts, are the most common method for capturing item data quickly and accurately. RFID tags, which can be read wirelessly and in bulk without direct line-of-sight, offer an even more advanced level of automation and speed, though they are generally more expensive.

These scanning devices are essential for real-time data entry and validation at every touchpoint in the warehouse.Integral to the system are handheld mobile computers or terminals. These devices, often ruggedized for warehouse environments, are equipped with scanners and connect wirelessly to the WMS. They empower warehouse staff to perform tasks like receiving, put-away, picking, and inventory counts directly at the point of activity, instantly updating the central database.

Inventory control and tracking mechanisms are built into the WMS, encompassing features like lot tracking, serial number tracking, expiration date management, and bin location management. This allows for granular control over inventory, essential for industries with specific regulatory or quality control requirements. Integration capabilities are also paramount. A fishbowl WMS must seamlessly integrate with other business systems, most notably an Enterprise Resource Planning (ERP) system.

This integration ensures that sales orders from the ERP are fed into the WMS for fulfillment, and shipment data from the WMS is sent back to the ERP for invoicing and financial reconciliation. Other potential integrations include e-commerce platforms, shipping carrier software, and manufacturing execution systems (MES). Hardware infrastructure, including a reliable wireless network (Wi-Fi) throughout the warehouse, is critical for enabling real-time communication between mobile devices and the WMS server.

In some advanced setups, automation technologies like automated guided vehicles (AGVs), automated storage and retrieval systems (AS/RS), and sophisticated conveyor systems can be integrated to further enhance efficiency and accuracy.

Challenges and Considerations in Implementing and Operating a Fishbowl Inventory Control Strategy.

Implementing and operating a fishbowl inventory control strategy, while offering significant advantages, presents a unique set of challenges and considerations that organizations must carefully address for successful adoption. One of the primary hurdles is the initial investment in technology and infrastructure. This includes the cost of WMS software licenses, hardware such as scanners, mobile terminals, and potentially RFID readers, as well as the necessary network upgrades to support real-time data flow across the entire warehouse.

The complexity of integrating the WMS with existing ERP systems and other business applications can also be a significant challenge, requiring specialized IT expertise and careful planning to ensure data consistency and prevent operational disruptions.Another critical consideration is change management and user adoption. Moving from traditional, often manual, inventory processes to a highly digitized and integrated system requires a substantial shift in how warehouse staff operate.

Comprehensive training programs are essential to ensure that all personnel understand the new workflows, the functionality of the WMS, and the importance of accurate data entry. Resistance to change can be a significant barrier, and effective communication about the benefits of the new system, along with ongoing support, is crucial for overcoming this. Data accuracy and integrity are paramount in a fishbowl system; if the initial data loaded into the system is inaccurate, or if ongoing data capture is flawed, the entire system’s reliability will be compromised.

This necessitates robust data validation processes, regular audits, and a culture that emphasizes precision in every transaction. Furthermore, scalability and flexibility are important considerations. As the business grows and its inventory needs evolve, the WMS must be able to scale accordingly. The system should be flexible enough to accommodate changes in product lines, order volumes, and operational processes without requiring a complete overhaul.The ongoing maintenance and support of the WMS and associated hardware also require careful planning.

Software updates, hardware repairs, and technical support are ongoing costs that need to be factored into the operational budget. Finally, defining clear operational processes and workflows is essential before implementation. A fishbowl system is only as effective as the processes it supports. Organizations need to meticulously map out their current operations and redesign them to align with the capabilities of the WMS, ensuring that every step from receiving to shipping is optimized for efficiency and accuracy.

Without this foundational work, the technology, no matter how advanced, will not yield its full potential.

Conceptual Diagram of Goods and Information Movement within a Fishbowl Warehouse.

Imagine a warehouse organized around a central hub, much like a fishbowl, where all inventory and information converge and are managed. This central hub is the Warehouse Management System (WMS), represented as the core of our conceptual diagram. All incoming and outgoing goods, along with their associated data, flow through this central point.The process begins with Receiving. Goods arrive at the dock doors.

Upon arrival, they are immediately scanned using handheld devices or fixed scanners, and this information – item ID, quantity, supplier, and any other relevant details – is transmitted wirelessly and in real-time to the WMS. This is the first inflow of information into our central hub. From receiving, the goods are then directed to the Put-Away Zone. Here, the WMS, based on predefined logic (e.g., item velocity, size, temperature requirements), assigns a specific storage location (bin, rack, shelf) for each item.

The warehouse associate uses their mobile terminal to confirm the put-away, updating the item’s location within the WMS. This action solidifies the inventory’s position in the “bowl.”Next is the Storage Area, the vast expanse where inventory resides. Each location is meticulously mapped and tracked by the WMS. When an order is received from the ERP system, it is fed into the WMS, triggering the Picking Process.

The WMS generates optimized pick lists and directs pickers via their mobile terminals to the exact locations of the items needed. As a picker retrieves an item, they scan it, confirming its removal from the storage location and updating its status to “picked” in the WMS. This movement of goods from storage to the picking cart, and the corresponding data update, is a critical information flow.Following picking, items move to the Packing and Staging Area.

Here, picked items are consolidated, verified against the order, and prepared for shipment. The WMS tracks this verification process, ensuring order accuracy. Once packed and ready for dispatch, the goods are moved to the Shipping Zone. The WMS generates shipping labels and documentation, and the final act of shipment is recorded by scanning the package, which deducts the items from inventory and updates their status to “shipped” in the WMS.

This is the final outflow of goods and information from the “bowl.”The information flow is continuous and bidirectional. The WMS is constantly receiving updates from the mobile devices and scanners, and it, in turn, is providing instructions and information back to the operational staff. This creates a closed-loop system where every movement and status change of inventory is logged, visible, and actionable in real-time, ensuring that the “fishbowl” remains transparent and accurately reflects the inventory at any given moment.

The ERP system acts as an external connection, feeding sales orders and receiving inventory updates, maintaining a synchronized view of the business’s overall stock.

Identifying the tangible benefits of adopting a fishbowl methodology for warehouse operations.: Fishbowl Warehouse Management

Transitioning to a fishbowl inventory management system offers a multitude of tangible benefits that directly impact a warehouse’s bottom line and operational effectiveness. This approach moves beyond traditional, often siloed, inventory tracking to create a unified, transparent system where all aspects of inventory movement are interconnected and visible. The advantages span from drastically improved accuracy and enhanced decision-making to significant gains in efficiency and cost savings.

Embracing this methodology isn’t just about adopting new software; it’s about fundamentally reshaping how a warehouse operates, leading to more robust and profitable outcomes.

Obtain direct knowledge about the efficiency of hris small business through case studies.

Inventory Accuracy Improvement Through Error Minimization

A fishbowl inventory management system fundamentally redefines how inventory accuracy is achieved by systematically addressing and minimizing errors across all critical warehouse processes. In receiving, manual data entry or disconnected systems are prone to mistakes like incorrect quantities, wrong item identification, or missed shipments. A fishbowl system, often integrated with barcode scanning or RFID technology, ensures that every item received is immediately and accurately recorded against purchase orders in real-time.

This immediate validation prevents discrepancies from entering the system in the first place. During the put-away process, the system guides staff to designated storage locations, reducing the likelihood of items being misplaced or stored incorrectly, which can lead to lost inventory or delays in picking.The picking process, a frequent source of errors due to manual order interpretation or outdated pick lists, is revolutionized.

Fishbowl systems generate optimized pick paths and provide clear, digital instructions to pickers, often via mobile devices. This not only speeds up picking but also drastically reduces errors like picking the wrong item, wrong quantity, or shorting an order. For instance, a picker attempting to scan an incorrect item at a location will receive an immediate alert, preventing the error from progressing.

Similarly, shipping is streamlined. Before an order leaves the warehouse, a final scan verifies that the correct items and quantities are being loaded onto the truck, cross-referenced against the customer’s order. This end-of-line verification acts as a crucial safeguard. By creating a continuous, validated flow of information from the moment goods enter the warehouse to the moment they leave, a fishbowl approach creates a self-correcting mechanism that dramatically boosts inventory accuracy.

This accuracy is not a static achievement but a dynamic, ongoing state, minimizing shrinkage, reducing the need for costly cycle counts, and ultimately ensuring that what the system says is in stock truly is.

Enhanced Inventory Visibility for Superior Decision-Making

The enhanced inventory visibility offered by a fishbowl approach is a cornerstone of its value proposition, empowering businesses to make far more informed and strategic decisions. With real-time data accessible across the organization, managers gain an unprecedented understanding of inventory levels, movement patterns, and demand trends. This granular visibility allows for precise adjustments to stock levels, moving away from the guesswork often associated with traditional systems.

For example, if a particular SKU shows a consistent uptick in sales over the past few weeks, the system can flag this trend, prompting a proactive decision to increase reorder points or place larger orders before a stockout occurs. Conversely, slow-moving items can be easily identified, allowing for targeted promotions or clearance strategies to prevent capital from being tied up in dead stock.This real-time insight is invaluable for reordering.

Instead of relying on periodic manual checks or fixed reorder points that might not reflect current demand, a fishbowl system can dynamically adjust reorder suggestions based on sales velocity, lead times, and even seasonality. This prevents both costly stockouts that lead to lost sales and customer dissatisfaction, and overstock situations that drain working capital and increase storage costs. Furthermore, the detailed historical data captured by the system provides a robust foundation for demand forecasting.

By analyzing past sales data, seasonal fluctuations, and promotional impacts, businesses can develop more accurate forecasts, leading to optimized purchasing and production schedules. Consider a scenario where a company historically over-ordered for a holiday season based on intuition. A fishbowl system, with its detailed sales history, can reveal that a specific product category, while popular, has a shorter shelf life and was frequently discounted at the end of the previous season.

This data-driven insight allows for a more strategic ordering approach, balancing sufficient stock with minimized risk of obsolescence. The ability to see what’s happening, when it’s happening, and to predict what might happen next is the essence of intelligent inventory management, directly facilitated by the comprehensive visibility a fishbowl system provides.

Increased Operational Efficiency and Throughput

A warehouse that transitions to a fishbowl management framework can expect a significant uplift in operational efficiency and overall throughput. The interconnected nature of the system eliminates many of the manual handoffs and data re-entry points that plague less integrated systems. This streamlining directly translates into faster order fulfillment times. When an order is placed, the system immediately allocates available stock, generates optimized picking routes, and provides clear instructions, reducing the time from order receipt to shipment.

For instance, a warehouse that previously took 24-48 hours to fulfill an order might see this reduced to 8-12 hours, significantly improving customer satisfaction and allowing for a higher volume of orders to be processed daily.Labor productivity also sees a marked improvement. With clear, digital instructions and optimized workflows, warehouse staff can spend less time searching for items or deciphering paperwork and more time on value-added tasks.

The reduction in errors also means less time spent on costly investigations, returns processing, and customer service interventions related to incorrect shipments. This allows for a more focused and productive workforce. Imagine a scenario where pickers are no longer wandering aisles based on paper pick lists, but are guided directly to the correct bin by a mobile scanner that confirms the item and quantity.

This not only speeds up the picking process but also minimizes the mental effort required, reducing fatigue and increasing accuracy. Furthermore, the ability to monitor key performance indicators (KPIs) in real-time, such as order cycle time, picking accuracy, and labor utilization, allows management to identify bottlenecks and areas for further optimization. This continuous improvement cycle, driven by data and enabled by the fishbowl system, leads to a consistently higher throughput and a more agile, responsive warehouse operation.

Five-Year Cost-Effectiveness Comparison of a Fishbowl System

The cost-effectiveness of a fishbowl inventory management system over a five-year period is a critical consideration for businesses. While the initial investment may seem substantial, the long-term savings and return on investment (ROI) often far outweigh the upfront costs. This comparison factors in not just the software and hardware but also the ongoing operational expenses and the significant potential savings derived from improved inventory control.| Cost Component | Year 1 | Year 2 | Year 3 | Year 4 | Year 5 | Total (5 Years) ||———————–|————–|————–|————–|————–|————–|—————–|| Initial Investment | $50,000 | $0 | $0 | $0 | $0 | $50,000 || Annual Operational Cost| $10,000 | $11,000 | $12,000 | $13,000 | $14,000 | $60,000 || Potential Savings | $25,000 | $35,000 | $45,000 | $55,000 | $65,000 | $225,000 || Total ROI | -$35,000 | -$24,000 | -$12,000 | $3,000 | $15,000 | $25,000+ |The initial investment includes the purchase of the software, necessary hardware such as barcode scanners and mobile devices, and initial implementation and training.

The annual operational cost covers software subscriptions, maintenance, ongoing training, and potential IT support. Potential savings are derived from a multitude of factors. Reduced stockouts prevent lost sales and customer churn, which can be a significant, often unquantified, cost. For example, a single lost sale due to an out-of-stock item might be $100, but the loss of that customer’s future business could be worth thousands over time.

Reduced overstock situations free up working capital, lower warehousing costs (less space, less handling, reduced risk of obsolescence), and minimize the need for costly markdowns. Improved inventory accuracy reduces losses due to shrinkage and errors, saving the cost of physically replacing or writing off unaccounted-for items. Increased labor efficiency means fewer staff are needed for the same output, or existing staff can handle a greater volume, leading to direct labor cost savings.The table illustrates a scenario where the initial investment is recouped within the fourth year, with a positive total ROI by the end of the fifth year.

The savings grow year-over-year as the system’s benefits become more deeply embedded in operations and as the accuracy and efficiency gains compound. For instance, a company experiencing an average of 5% inventory shrinkage with a $1,000,000 inventory value could save $50,000 annually by reducing shrinkage to 0%. Similarly, avoiding just two major stockouts per year, each costing $10,000 in lost profit and goodwill, could generate $20,000 in annual savings.

The ROI calculation, therefore, is not just about direct cost reduction but also about increased revenue potential and improved capital utilization.

“The true cost of inventory is not just what you pay for it, but what it costs you to manage, store, and the potential lost revenue when it’s not available.”

Exploring the practical implementation steps for transitioning to a fishbowl warehouse management system.

Transitioning to a fishbowl warehouse management system marks a significant operational upgrade, promising enhanced efficiency and accuracy. This process, however, requires meticulous planning and execution to ensure a smooth shift from existing systems. A well-defined strategy, encompassing distinct phases, is crucial for minimizing disruption and maximizing the benefits of the new fishbowl approach. This section Artikels the essential steps involved in a successful migration, from initial assessment to full operational integration.The successful implementation of a fishbowl warehouse management system hinges on a structured, phased approach.

Each phase is designed to build upon the previous one, ensuring that all aspects of the transition are thoroughly addressed. This methodical progression allows for the identification and mitigation of potential challenges, ultimately leading to a robust and efficient warehouse operation.

Project Plan for Migrating to a Fishbowl Solution

A comprehensive project plan is the bedrock of a successful migration from a legacy system to a fishbowl solution. This plan should be iterative, allowing for adjustments as the project progresses, and should clearly define responsibilities, timelines, and key deliverables for each phase. The ultimate goal is to achieve a seamless transition with minimal impact on ongoing operations.The project plan can be broken down into the following critical phases:

- Phase 1: Assessment and Planning (Weeks 1-4)

- Conduct a thorough audit of current warehouse processes, identifying pain points and areas for improvement.

- Document existing workflows, inventory levels, and system integrations.

- Define clear objectives and key performance indicators (KPIs) for the fishbowl system.

- Form a dedicated project team with representatives from IT, warehouse operations, and management.

- Develop a detailed budget and resource allocation plan.

- Identify potential risks and develop mitigation strategies.

- Phase 2: Selection and Procurement (Weeks 5-8)

- Research and evaluate various fishbowl warehouse management software vendors based on predefined requirements.

- Request demonstrations and conduct trials to assess software functionality and user-friendliness.

- Verify vendor reputation, customer support, and long-term viability.

- Negotiate contracts and finalize the selection of the fishbowl solution.

- Procure necessary hardware, such as scanners, mobile devices, and network infrastructure.

- Phase 3: Configuration and Customization (Weeks 9-16)

- Work closely with the vendor to configure the fishbowl system according to specific business needs.

- Define warehouse layout, bin locations, and product hierarchies within the system.

- Set up user roles, permissions, and access levels.

- Integrate the fishbowl system with existing ERP, accounting, and shipping software.

- Develop custom reports and dashboards as required.

- Phase 4: Data Migration and Cleansing (Weeks 17-20)

- Extract data from the legacy system, ensuring data integrity.

- Cleanse and de-duplicate data to eliminate inaccuracies and redundancies.

- Map legacy data fields to the corresponding fields in the fishbowl system.

- Perform test migrations to validate the data transfer process.

- Execute the final data migration.

- Phase 5: Testing and Validation (Weeks 21-24)

- Conduct comprehensive user acceptance testing (UAT) to ensure the system meets operational requirements.

- Test all critical workflows, including receiving, put-away, picking, packing, and shipping.

- Simulate various scenarios, including stockouts, returns, and rush orders.

- Address and resolve any bugs or issues identified during testing.

- Obtain sign-off from key stakeholders.

- Phase 6: Training and Go-Live (Weeks 25-28)

- Develop and deliver comprehensive training programs for all warehouse staff.

- Provide hands-on training sessions and create user manuals.

- Execute a phased or full go-live strategy, depending on the complexity of the operation.

- Provide on-site support during the initial go-live period.

- Establish a post-go-live support and optimization plan.

- Phase 7: Post-Implementation Review and Optimization (Ongoing)

- Monitor system performance and user adoption.

- Gather feedback from users and identify areas for further optimization.

- Conduct regular system audits and data integrity checks.

- Implement updates and enhancements as needed.

Essential Training Protocols for Warehouse Staff

Effective training is paramount to the successful adoption and utilization of a fishbowl warehouse management system. Without adequate training, even the most sophisticated software can lead to errors and inefficiencies. The training program should be tailored to the specific roles and responsibilities of each team member, ensuring they are comfortable and proficient with the new system’s functionalities.A robust training protocol should encompass the following key areas:

- System Navigation and User Interface Familiarization:

- Introduction to the fishbowl software’s main dashboard and navigation menus.

- Understanding the layout of different modules and their purpose.

- Basic operations such as logging in, logging out, and accessing help resources.

- Data Entry and Accuracy:

- Correct procedures for entering new inventory items, including product details, SKUs, and quantities.

- Guidelines for updating existing inventory records, such as receiving new stock or adjusting quantities.

- Emphasis on the importance of accurate data entry to maintain inventory integrity.

- Techniques for minimizing data entry errors, such as using dropdown menus and validation rules.

- Scanning Procedures and Barcode Utilization:

- Proper use of barcode scanners for receiving, put-away, picking, and cycle counting.

- Understanding different types of barcodes and their encoding.

- Troubleshooting common scanning issues, such as unreadable barcodes or scanner connectivity problems.

- Demonstrating how scanning automates processes and reduces manual input.

- Inventory Management Workflows:

- Step-by-step guidance on receiving processes, including verifying shipments against purchase orders.

- Training on put-away strategies and efficient location management.

- Detailed instructions for order picking, including different picking methods (e.g., single order, batch picking).

- Procedures for packing orders accurately and preparing them for shipment.

- Understanding cycle counting and physical inventory processes.

- Exception Handling and Problem Solving:

- Identifying and addressing common exceptions, such as damaged goods, incorrect shipments, or inventory discrepancies.

- Procedures for reporting and resolving issues within the fishbowl system.

- Training on how to use the system’s reporting features to investigate problems.

- Empowering staff to proactively identify and escalate potential issues.

- Reporting and Analytics:

- Basic understanding of key reports generated by the fishbowl system (e.g., inventory levels, order status, movement history).

- How to access and interpret these reports to gain insights into warehouse performance.

- Training on how to use custom reports if applicable.

- Safety and Compliance:

- Reinforcing safety protocols within the warehouse context, especially when using new equipment or procedures.

- Ensuring staff understand how the fishbowl system supports compliance with relevant regulations.

Training should be an ongoing process, with refresher courses and advanced modules introduced as staff gain experience and the system evolves. Utilizing a blend of classroom instruction, hands-on practice, and e-learning modules can cater to different learning styles and ensure comprehensive knowledge transfer.

Best Practices for Data Migration and Cleansing

The integrity of your inventory records is foundational to the success of any warehouse management system, and a fishbowl approach is no exception. Before migrating data to a new fishbowl system, a rigorous process of data cleansing and migration best practices must be implemented. This ensures that the new system starts with accurate, reliable information, preventing the perpetuation of existing errors and setting the stage for optimal performance.Adhering to these best practices is crucial for a clean and accurate data migration:

- Understand Your Data Landscape:

- Conduct a comprehensive audit of all data sources from the legacy system.

- Identify all data fields relevant to inventory management, including product master data, stock levels, locations, and historical transaction data.

- Categorize data based on its importance and frequency of use.

- Define Data Cleansing Rules:

- Establish clear criteria for identifying and correcting data anomalies.

- This includes standardizing units of measure, correcting typos, and resolving duplicate entries.

- For example, if a product is listed as “Box” and “Bx” in different records, a rule should dictate that it be standardized to “Box”.

- De-duplication and Standardization:

- Implement automated tools or manual processes to identify and merge duplicate records.

- Standardize product names, descriptions, and other attributes to ensure consistency across all entries.

- For instance, ensuring all instances of “Widget Pro” are consistently represented.

- Data Validation and Verification:

- Cross-reference data with physical inventory counts or other reliable sources where possible.

- Implement validation checks to ensure data conforms to expected formats and ranges.

- For example, verifying that stock quantities are not negative unless explicitly allowed for backorders.

- Data Transformation and Mapping:

- Create a clear mapping document that defines how data fields from the legacy system will correspond to fields in the fishbowl system.

- Transform data formats as necessary to be compatible with the new system’s requirements.

- This might involve converting date formats or adjusting numerical precision.

- Incremental Data Migration:

- For large datasets, consider migrating data in batches rather than all at once.

- This allows for easier identification and correction of issues during the migration process.

- Start with less critical data sets to refine the process before moving to core inventory information.

- Test Migration:

- Perform multiple test migrations in a sandbox or staging environment.

- This allows you to identify and resolve any technical issues or data discrepancies before the final migration.

- Analyze the results of test migrations thoroughly to ensure accuracy and completeness.

- Backup and Archiving:

- Ensure a complete backup of the legacy data is securely stored before commencing the migration.

- Develop a strategy for archiving historical data that is not migrated to the new system but may be needed for compliance or reference.

- Post-Migration Validation:

- Immediately after the final migration, conduct a thorough validation of the data in the fishbowl system.

- Perform spot checks on key inventory items and locations.

- Monitor the system for any data-related errors or anomalies that may arise.

A well-executed data migration and cleansing process is not a one-time event but rather an ongoing commitment to data quality. Regularly scheduled data audits and maintenance within the fishbowl system will help maintain the integrity of your inventory records over time.

Critical Considerations for Selecting the Right Fishbowl Warehouse Management Software

Choosing the appropriate fishbowl warehouse management software is a strategic decision that profoundly impacts operational efficiency, scalability, and profitability. The market offers a variety of solutions, each with its unique strengths and features. A thorough evaluation process, considering several critical factors, is essential to ensure the selected software aligns perfectly with current and future business needs.When evaluating fishbowl warehouse management software, pay close attention to the following considerations:

- Scalability and Future Growth:

- The software should be capable of handling your current inventory volume and transactions with ease.

- More importantly, it must be able to scale seamlessly as your business grows, accommodating increased SKUs, higher transaction volumes, and potentially new warehouse locations without requiring a complete system overhaul.

- Consider whether the vendor offers tiered pricing or modules that can be added as your needs expand.

- Integration Capabilities with Existing Systems:

- Seamless integration with your existing Enterprise Resource Planning (ERP) system is paramount.

- This ensures that data flows bi-directionally and in real-time between your ERP and the warehouse management system, eliminating manual data entry and reducing errors.

- Assess compatibility with other critical business software, such as accounting packages, shipping carriers, and e-commerce platforms.

- Look for systems that offer robust APIs (Application Programming Interfaces) or pre-built connectors for common software.

- Vendor Support and Reliability:

- Evaluate the vendor’s track record, financial stability, and commitment to customer support.

- What are their support hours, response times, and available channels (phone, email, chat)?

- Understand their update and maintenance schedule for the software.

- Seek out customer testimonials and case studies to gauge their reliability and customer satisfaction.

- Functionality and Features:

- Does the software offer the specific features your warehouse operations require?

- This could include advanced inventory tracking (e.g., lot or serial number tracking), kitting, wave picking, cross-docking, returns management, and labor management.

- Prioritize features that directly address your current pain points and operational goals.

- User-Friendliness and Ease of Adoption:

- The system should have an intuitive interface that is easy for your warehouse staff to learn and navigate.

- A complex system with a steep learning curve can lead to resistance and underutilization.

- Consider the availability of training resources and documentation provided by the vendor.

- Reporting and Analytics Capabilities:

- The software should provide comprehensive reporting and analytics tools to give you visibility into your warehouse operations.

- This includes real-time inventory levels, order fulfillment rates, picking accuracy, and labor productivity.

- The ability to create custom reports tailored to your specific KPIs is a significant advantage.

- Total Cost of Ownership (TCO):

- Look beyond the initial purchase price. Consider ongoing costs such as subscription fees, maintenance, support, hardware upgrades, and potential customization costs.

- A seemingly cheaper solution upfront might have higher long-term costs.

- Mobile Capabilities and Hardware Compatibility:

- If your operations rely on mobile devices and scanners, ensure the software fully supports these technologies.

- Check for compatibility with your preferred hardware and operating systems (e.g., iOS, Android, Windows Mobile).

A thorough due diligence process, including demos, trials, and speaking with existing users, will help you make an informed decision and select a fishbowl warehouse management software that truly empowers your operations for years to come.

Examining Advanced Functionalities and Integration Possibilities Within a Fishbowl Warehouse Environment

A robust warehouse management system (WMS) like Fishbowl is not an isolated entity; its true power is unleashed when it becomes an integrated hub within a broader business ecosystem. This section delves into how Fishbowl transcends basic inventory tracking to offer sophisticated functionalities and seamless integration capabilities, transforming a warehouse from a cost center into a strategic advantage. We will explore how it communicates with other critical business systems, leverages real-time data for enhanced decision-making, and incorporates automation to streamline operations.

Furthermore, we will illustrate its adaptability in handling complex order fulfillment scenarios.

Fishbowl System Integration with Other Business Systems

The concept of a unified operational ecosystem is paramount in modern business, and Fishbowl plays a pivotal role in achieving this through its extensive integration capabilities. By connecting with Enterprise Resource Planning (ERP) systems, Order Management Systems (OMS), and Transportation Management Systems (TMS), Fishbowl breaks down data silos and fosters a holistic view of operations. Integrating with an ERP system, such as SAP or Oracle, allows for the seamless flow of financial data, production planning, and customer relationship management information directly into the WMS.

This means that inventory levels in Fishbowl are automatically reflected in the ERP’s financial statements, and procurement decisions can be informed by real-time stock availability. Similarly, integration with an OMS streamlines the entire order lifecycle. When an order is placed through an e-commerce platform or a sales representative’s interface, the OMS can push this information to Fishbowl, which then allocates inventory, generates picking lists, and initiates the fulfillment process.

Conversely, as orders are shipped and updated in Fishbowl, this information is fed back to the OMS, updating order status for customers and sales teams. The synergy with a TMS is equally crucial for optimizing logistics. By integrating Fishbowl with a TMS, companies can automate the selection of carriers, generate shipping labels, and track shipments in real-time. This allows for better freight cost management, improved delivery times, and enhanced visibility into the entire supply chain, from warehouse picking to final delivery.

This interconnectedness ensures that all departments are working with the same, up-to-date information, reducing errors, improving efficiency, and ultimately enhancing customer satisfaction. For instance, a retail company can leverage this integration to ensure that online orders are fulfilled promptly, with accurate inventory counts and efficient shipping, thereby meeting customer expectations and maintaining a competitive edge.

Real-Time Data Capture and Analytics for Proactive Problem-Solving

The ability to capture and analyze data in real-time is a cornerstone of effective warehouse management, and Fishbowl excels in providing this capability. Within the Fishbowl framework, every transaction – from receiving goods to picking, packing, and shipping – is captured instantaneously. This constant stream of data fuels powerful analytical tools that empower businesses to move from reactive problem-solving to proactive intervention.

Do not overlook explore the latest data about hr management systems for small business.

For example, by monitoring real-time inventory turnover rates, managers can identify slow-moving or obsolete stock before it becomes a significant financial burden. Similarly, analyzing picking times and order fulfillment accuracy in real-time allows for the immediate identification of bottlenecks or training needs among warehouse staff. This granular visibility extends to tracking key performance indicators (KPIs) such as order cycle time, perfect order rate, and dock-to-stock time.

When these metrics deviate from established benchmarks, Fishbowl’s analytics can pinpoint the exact stage in the process where the issue is occurring, enabling swift corrective actions. Consider a scenario where order fulfillment times suddenly increase. Real-time analytics within Fishbowl can reveal whether the delay is due to slow picking, insufficient packing materials, or issues with shipping carrier pickups. This allows management to address the specific cause rather than guessing.

Furthermore, these analytics provide the foundation for continuous process improvement initiatives. By understanding historical data trends and identifying recurring inefficiencies, businesses can strategically reconfigure warehouse layouts, optimize picking routes, or implement new workflows to enhance productivity and reduce operational costs. The predictive capabilities, often powered by machine learning algorithms integrated with the WMS, can even forecast future demand based on historical sales data and market trends, allowing for proactive inventory adjustments and labor scheduling.

This data-driven approach transforms the warehouse into a highly efficient and responsive operation, capable of adapting to changing market demands and operational challenges.

Automation Technologies and Fishbowl Management System Synergy

The integration of automation technologies with a Fishbowl warehouse management system represents the next frontier in optimizing warehouse operations and significantly reducing manual intervention. Automated Guided Vehicles (AGVs) and robotic arms are no longer futuristic concepts but practical tools that, when orchestrated by a sophisticated WMS like Fishbowl, can revolutionize efficiency and accuracy. AGVs, for instance, can be programmed to autonomously transport goods from receiving docks to storage locations, or from storage to packing stations, following pre-defined routes.

Fishbowl can direct these AGVs based on real-time inventory needs, ensuring that materials are moved precisely when and where they are required, minimizing human travel time and the associated risks of accidents. Robotic arms, on the other hand, excel at repetitive and physically demanding tasks. They can be deployed for palletizing, depalletizing, or even picking individual items from shelves. Fishbowl’s WMS provides the intelligence, dictating which items to pick, in what quantities, and to which destination, while the robotic arm executes the physical task with unparalleled speed and precision.

Get the entire information you require about hr management software for small business on this page.

This synergy is particularly impactful in high-volume environments where human error and fatigue can lead to significant discrepancies. For example, a large e-commerce distribution center can utilize robotic arms to pick and pack hundreds of small orders per hour, with Fishbowl ensuring that the correct items are picked for each order and that inventory levels are updated in real-time. The WMS acts as the brain, processing orders and allocating tasks, while the automation technologies serve as the highly efficient hands and feet.

This not only accelerates throughput but also improves ergonomics for human workers, allowing them to focus on more complex, value-added tasks such as quality control, exception handling, and strategic planning. The reduction in manual handling also leads to a decrease in product damage and a more consistent workflow, ultimately contributing to lower operational costs and higher customer satisfaction due to faster and more accurate order fulfillment.

Workflow for Complex Order Fulfillment Scenarios in Fishbowl, Fishbowl warehouse management

Fishbowl’s inherent flexibility and adaptability are vividly demonstrated in its ability to manage complex order fulfillment scenarios, such as kitting, assembly, and multi-channel order processing. These intricate workflows are handled with precision, ensuring accuracy and efficiency even when dealing with varied product configurations and sales channels. For kitting, where multiple individual SKUs are bundled together to form a single sellable unit, Fishbowl manages the component inventory separately while treating the kit as a distinct product.

When a kit order is received, Fishbowl automatically allocates the necessary component parts from their respective locations, triggers the kitting process, and updates the inventory of both the components (decrementing them) and the finished kit (incrementing it). This ensures that the bill of materials is accurately consumed and that stock levels for individual components remain precise. Similarly, for assembly operations, where products are built to order from raw materials or sub-assemblies, Fishbowl tracks the entire production process.

It manages the release of work orders, issues raw materials to production, tracks labor and overhead, and records the completion of finished goods. This provides end-to-end visibility into the manufacturing and assembly process, allowing for accurate costing and scheduling. Multi-channel order processing is another area where Fishbowl shines. Whether orders originate from an e-commerce website, a brick-and-mortar store, a wholesale portal, or a marketplace like Amazon, Fishbowl can consolidate these orders into a single, unified queue.

The system then intelligently allocates inventory based on predefined rules, such as proximity of inventory to the customer, shipping costs, or order priority. This ensures that inventory is managed efficiently across all sales channels, preventing overselling and enabling faster fulfillment. For instance, a company selling on its own website and through Amazon can configure Fishbowl to prioritize fulfilling orders from the channel with the highest profit margin or the fastest delivery commitment.

The system can also handle backorders gracefully, automatically notifying customers and prioritizing replenishment when stock becomes available. The workflow for a complex multi-channel order might begin with an order placed on a website, which is immediately captured by Fishbowl. If the order involves a kitted product, Fishbowl will initiate the kit assembly process, drawing the required components. Once the kit is assembled, it is picked, packed, and shipped.

Simultaneously, another order from Amazon for a different product might be processed, with Fishbowl allocating available stock and generating a shipping label through its TMS integration. This seamless orchestration of diverse fulfillment requirements highlights Fishbowl’s capacity to adapt to evolving business needs and complex operational landscapes.

Addressing Potential Challenges and Mitigation Strategies for Fishbowl Warehouse Management

Transitioning to a fishbowl warehouse management system, while offering significant advantages, is not without its hurdles. Proactive identification and strategic planning for potential challenges are crucial for a successful implementation and sustained operational efficiency. Understanding these common pitfalls and their corresponding solutions empowers organizations to navigate the complexities of this inventory control methodology with greater confidence and achieve the desired outcomes.

Common Pitfalls and Practical Solutions

Implementing a fishbowl warehouse management system can present several common challenges that, if left unaddressed, can impede progress and diminish the anticipated benefits. These issues often stem from inadequate preparation, resistance to change, or a lack of understanding of the system’s nuances.One prevalent pitfall is inaccurate initial data entry. This can lead to incorrect stock levels, misallocated inventory, and ultimately, flawed decision-making.

The solution lies in rigorous data validation processes before and during the migration. This includes conducting thorough physical inventory counts, cross-referencing existing records, and implementing data cleansing protocols. Utilizing barcode scanning for all incoming and outgoing inventory can significantly reduce manual entry errors. Furthermore, establishing clear data ownership and accountability ensures ongoing accuracy.Another frequent challenge is resistance to change from warehouse staff. Employees accustomed to traditional methods may find the new system complex or disruptive.

Effective mitigation involves comprehensive and ongoing training tailored to different user roles. Demonstrating the system’s benefits, such as reduced manual effort and improved accuracy, can foster buy-in. Involving key staff members in the selection and implementation process, making them champions of the new system, can also be highly effective. Regular feedback sessions and addressing concerns promptly are vital for maintaining morale and encouraging adoption.A third significant challenge is underestimating the complexity of integration with existing systems.

Fishbowl often needs to interface with accounting software, e-commerce platforms, or other business applications. Without proper planning, integration can be a source of bugs, data discrepancies, and workflow disruptions. The key to overcoming this is meticulous planning and testing. Engaging with IT professionals and the Fishbowl support team early in the process to map out integration points and data flows is essential.

Thorough testing of all integrated workflows in a sandbox environment before going live can prevent costly errors.Finally, inadequate system configuration can lead to inefficiencies. Failing to tailor the system to specific operational needs, such as unique product types, complex picking routes, or specific kitting requirements, can result in suboptimal performance. The solution is to invest time in understanding and configuring the system’s parameters to match the organization’s unique workflows.

This might involve working with a Fishbowl implementation partner to fine-tune settings, define custom fields, and optimize reporting for specific business metrics.

Critical Success Factors for Adoption

The successful adoption of a fishbowl inventory control strategy hinges on a confluence of factors, with organizational change management and user buy-in standing as paramount. Without a concerted effort to prepare the organization and its people for the transition, even the most sophisticated system will struggle to deliver its full potential. Strong leadership commitment is the bedrock of successful change. When senior management actively champions the fishbowl approach, it signals its importance to the entire organization and allocates the necessary resources.

This commitment should be visible through communication, participation in key decisions, and unwavering support for the implementation team. Effective communication throughout the implementation process is equally critical. This involves clearly articulating the reasons for adopting the fishbowl system, outlining the expected benefits, and providing regular updates on progress. Transparency about potential challenges and how they are being addressed helps to build trust and reduce anxiety among staff.

Communication channels should be open, allowing for questions and feedback to be readily shared and acted upon. Comprehensive and ongoing training is non-negotiable. Users must not only understand how to operate the system but also grasp the underlying principles of the fishbowl methodology. Training should be role-specific and delivered in a way that is accessible and engaging. Beyond initial training, continuous learning opportunities, refresher courses, and readily available support resources are essential to ensure users remain proficient and adapt to system updates or evolving operational needs.

User buy-in is cultivated through involvement and demonstrated value. Empowering key users to participate in system testing, providing input on configurations, and recognizing their contributions can foster a sense of ownership. When employees see how the fishbowl system directly benefits their daily tasks by reducing errors, improving efficiency, and providing clearer information, their willingness to embrace it increases significantly. Creating a positive feedback loop where user suggestions are considered and implemented further strengthens this buy-in.

Phased implementation can also be a critical success factor, especially for larger or more complex operations. Rolling out the fishbowl system in stages, starting with a pilot group or a specific area of the warehouse, allows for learning and refinement before a full-scale deployment. This approach minimizes disruption and provides opportunities to address unforeseen issues in a controlled environment.

Robust Data Security and Backup Protocols

In the realm of warehouse management, particularly with a system like Fishbowl that centralizes critical inventory and operational data, robust data security and comprehensive backup protocols are not merely good practices; they are indispensable pillars of business continuity and integrity. The information managed by a fishbowl system—including stock levels, order histories, customer data, and financial transactions—is highly sensitive and vital for daily operations.

Any compromise or loss of this data can lead to significant financial losses, reputational damage, and operational paralysis.Data security measures must encompass multiple layers of protection. Access control is fundamental. This involves implementing granular user permissions, ensuring that only authorized personnel can access specific data modules or perform certain actions within the system. Strong password policies, multi-factor authentication, and regular audits of user access logs are essential to prevent unauthorized entry.

Encryption of sensitive data, both in transit and at rest, adds another crucial layer of defense against breaches.Beyond preventing external threats, internal security protocols are equally important. This includes training employees on data handling best practices, recognizing phishing attempts, and understanding the importance of safeguarding login credentials. Physical security of the servers or devices hosting the Fishbowl system is also a consideration, preventing unauthorized physical access.

Regular vulnerability assessments and penetration testing can help identify and address potential weaknesses in the system’s security posture before they can be exploited.Equally critical are comprehensive data backup and disaster recovery plans. Regular, automated backups of the entire Fishbowl database are non-negotiable. These backups should be stored securely, ideally off-site or in a cloud-based solution, to protect against physical disasters such as fire, flood, or theft that could affect the primary location.

The frequency of backups should align with the volume of data changes; for high-transaction environments, daily or even more frequent backups might be necessary.A well-defined disaster recovery plan Artikels the procedures for restoring data and resuming operations in the event of a major disruption. This plan should be documented, regularly tested, and understood by key personnel. Testing involves simulating various disaster scenarios to ensure that the backup restoration process is efficient and that the business can return to normal operations within an acceptable timeframe.

This includes having a clear recovery point objective (RPO) and recovery time objective (RTO) that align with business needs.

Performance Metrics in a Fishbowl Warehouse Environment

To effectively gauge the performance and success of a fishbowl warehouse management system, a suite of key performance indicators (KPIs) is typically monitored. These metrics provide quantifiable insights into operational efficiency, accuracy, and the overall health of inventory management. Regularly tracking these KPIs allows for timely identification of areas needing improvement and demonstrates the tangible value delivered by the system.Here are some critical performance metrics commonly monitored in a fishbowl warehouse environment:

- Inventory Turnover Rate: This metric measures how many times inventory is sold and replaced over a specific period. A higher turnover rate generally indicates efficient inventory management, as it suggests that stock is moving quickly and not sitting idle.

Inventory Turnover Rate = Cost of Goods Sold / Average Inventory Value

- Order Accuracy Rate: This KPI tracks the percentage of orders that are fulfilled correctly, without errors in items, quantities, or shipping information. High order accuracy is crucial for customer satisfaction and minimizing costly returns or redeliveries.

Order Accuracy Rate = (Total Orders – Orders with Errors) / Total Orders

– 100% - Cycle Count Variance: Cycle counting involves regularly counting small subsets of inventory to verify accuracy against system records. Variance measures the discrepancy between the physical count and the recorded stock level. Low variance indicates accurate record-keeping and effective inventory control.

- On-Time Shipment Rate: This metric measures the percentage of orders that are shipped by the promised or scheduled date. Meeting on-time shipment targets is vital for maintaining customer trust and operational reliability.

- Picking Accuracy: Similar to order accuracy, this metric focuses specifically on the accuracy of the picking process within the warehouse. It measures the percentage of items picked correctly for each order.

- Warehouse Capacity Utilization: This KPI assesses how effectively the available warehouse space is being used. Optimizing capacity can reduce storage costs and improve workflow efficiency.

- Receiving Accuracy: This measures the accuracy of incoming inventory. It tracks discrepancies between what is ordered and what is actually received, ensuring that all goods are accounted for upon arrival.

- Dock-to-Stock Time: This metric measures the time it takes for received goods to be put away into their designated storage locations. Shorter dock-to-stock times improve inventory availability and reduce potential damage or loss of goods in transit within the warehouse.

Conclusion

In essence, the fishbowl warehouse management system offers a powerful framework for modern inventory control, providing a clear path to enhanced accuracy, operational efficiency, and strategic decision-making. By carefully considering implementation steps, exploring advanced functionalities, and proactively addressing potential challenges, businesses can successfully transition to and thrive within this innovative management approach, ultimately driving greater profitability and customer satisfaction.

FAQ Compilation

What is the primary difference between fishbowl warehouse management and traditional methods?

The primary difference lies in the integrated and real-time nature of fishbowl systems. Traditional methods often rely on manual tracking or siloed software, leading to delays and inaccuracies. Fishbowl emphasizes a central hub of information, with all processes feeding into and drawing from it, providing immediate visibility and control.

What are the essential hardware components for a fishbowl warehouse management system?

Essential hardware typically includes barcode scanners (handheld, ring, or wearable), mobile computers or tablets for on-the-go data entry, reliable Wi-Fi infrastructure throughout the warehouse, and potentially label printers. The specific hardware will depend on the scale and complexity of the operation.

How does fishbowl warehouse management improve order fulfillment times?

By providing real-time inventory visibility and optimized picking paths, fishbowl systems reduce the time spent searching for items. Streamlined put-away processes ensure items are stored logically, and efficient shipping workflows minimize delays, all contributing to faster and more accurate order fulfillment.

What kind of training is typically required for warehouse staff using a fishbowl system?

Staff require training on using scanners, mobile devices, and the specific software interface for tasks like receiving, put-away, picking, and shipping. Training also covers understanding data entry accuracy, handling exceptions or discrepancies, and the importance of real-time updates.

Can a fishbowl system integrate with existing ERP systems?

Yes, a key advantage of many fishbowl warehouse management solutions is their ability to integrate with existing Enterprise Resource Planning (ERP) systems. This integration creates a unified ecosystem, ensuring data consistency across different business functions.