Manufacturing management software sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail with casual formal language style and brimming with originality from the outset.

This comprehensive guide delves into the multifaceted world of manufacturing management software, exploring its core functionalities, strategic implementation, transformative impact on production, and future trajectory. We will dissect how these powerful systems streamline operations, optimize resource allocation, enhance quality control, and leverage real-time data for continuous improvement. Furthermore, we will navigate the diverse landscape of available solutions, considering deployment models, industry-specific needs, customization options, vendor support, and financial implications.

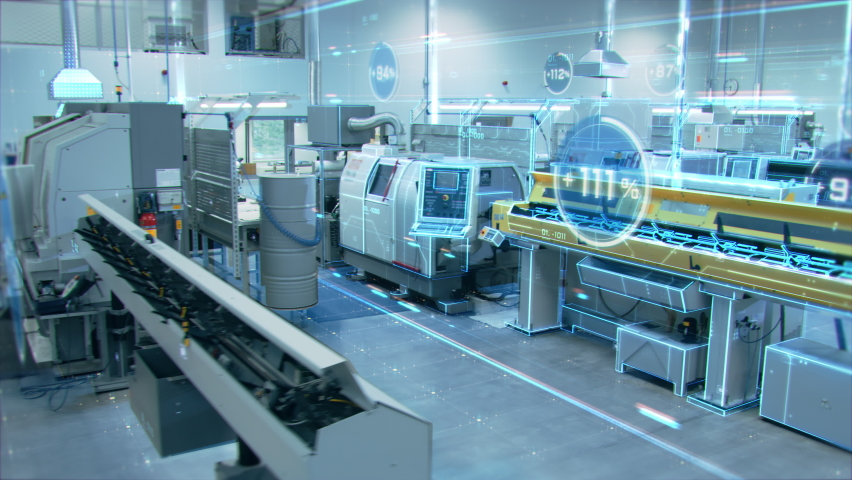

The transformative power of this software on shop floor operations and workforce productivity will be illuminated through practical scenarios and change management strategies. Finally, we will peer into the future, examining the integration of AI, IoT, AR/VR, and blockchain technologies that are poised to revolutionize manufacturing.

Unpacking the Core Functionalities of Manufacturing Management Software for Enhanced Operational Efficiency

Manufacturing management software, often referred to as Manufacturing Execution Systems (MES) or Enterprise Resource Planning (ERP) with manufacturing modules, is the digital backbone of modern production facilities. These comprehensive systems are designed to provide end-to-end visibility and control over every facet of the manufacturing process, from the initial raw material order to the final product shipment. Their primary objective is to move beyond basic data recording and instead actively guide, monitor, and optimize operations.

By centralizing information and automating workflows, these platforms empower manufacturers to make data-driven decisions, respond swiftly to market changes, and ultimately achieve significant improvements in efficiency, quality, and profitability. The implementation of such software is not merely an IT upgrade; it’s a strategic transformation that reshapes how production is planned, executed, and managed, leading to a more agile, responsive, and competitive enterprise.

Production Planning, Scheduling, and Resource Allocation

The ability to effectively plan, schedule, and allocate resources is fundamental to achieving streamlined production. Manufacturing management software excels in this area by providing robust tools that translate demand into actionable production plans. These systems can forecast material and labor requirements based on historical data, current orders, and anticipated future demand. This forecasting capability allows for proactive procurement and workforce management, preventing costly shortages or overstaffing.The scheduling functionalities are equally critical.

Instead of relying on manual spreadsheets or disparate systems, these software platforms offer sophisticated algorithms that can optimize production sequences. This includes considering machine availability, operator skill sets, material lead times, and due dates to create efficient production schedules. The software can dynamically adjust schedules in real-time when unforeseen events occur, such as equipment breakdowns or rush orders, ensuring minimal disruption and maximum throughput.

For instance, a complex assembly line might have dozens of interdependent steps; the software can map out the optimal order and timing for each step, accounting for the specific capabilities of each workstation and the availability of trained personnel.Resource allocation is also precisely managed. The software can identify the specific machines, tools, and personnel required for each production order. This ensures that resources are utilized to their fullest potential, minimizing idle time and maximizing capacity.

It can also flag potential resource conflicts, allowing managers to resolve them before they impact the production schedule. This intelligent allocation prevents scenarios where a critical machine is booked for a low-priority task while a high-priority order waits, or where a skilled operator is assigned to a task that a less experienced worker could handle, freeing up expertise for more complex operations.

The integration of these planning, scheduling, and allocation functions within a single system creates a cohesive and optimized production flow, driving substantial gains in operational efficiency and reducing overall production costs.

Inventory Control and Materials Management

Effective inventory control and materials management are cornerstones of reducing waste and optimizing stock levels, directly impacting a manufacturer’s bottom line. Manufacturing management software provides comprehensive tools to achieve this. These systems offer real-time visibility into inventory levels across all locations, from raw materials and work-in-progress to finished goods. This eliminates the guesswork associated with manual tracking, which is prone to errors and discrepancies.The software facilitates precise demand forecasting, which is crucial for preventing both stockouts and overstocking.

By analyzing historical sales data, production schedules, and lead times from suppliers, the system can predict the exact quantities of materials needed and when they will be required. This allows for just-in-time (JIT) inventory practices, where materials arrive precisely when they are needed for production, thereby minimizing storage costs, reducing the risk of obsolescence, and freeing up working capital. For example, a food manufacturer can use the software to predict the demand for specific ingredients based on seasonal trends and promotional campaigns, ensuring that perishable items are ordered in optimal quantities to avoid spoilage.Furthermore, these systems enable robust lot and serial number tracking.

This is vital for quality control, traceability, and recall management. If a defect is identified in a batch of products, the software can quickly pinpoint the specific raw materials used, the production batches involved, and the customers who received the affected items. This granular level of detail is invaluable for regulatory compliance and for minimizing the impact of any quality issues.

The software also supports various inventory valuation methods, helping businesses maintain accurate financial records and make informed purchasing decisions. By automating many of the tedious tasks associated with inventory management, such as cycle counting and stock adjustments, these systems free up valuable employee time to focus on more strategic activities. The overall outcome is a lean, efficient inventory system that minimizes waste, reduces holding costs, and ensures that the right materials are available at the right time, every time.

Quality Control Modules for Defect Reduction and Consistent Product Standards

Maintaining high product quality is paramount for customer satisfaction, brand reputation, and long-term business success. Quality control modules within manufacturing management software play a pivotal role in achieving defect reduction and ensuring consistent product standards throughout the production lifecycle. These modules move quality management from a reactive, inspection-based approach to a proactive, process-integrated one.The software allows for the establishment of defined quality checks at various stages of the manufacturing process.

This can include incoming material inspections, in-process checks at critical assembly points, and final product testing. For each inspection, specific parameters, tolerances, and acceptable quality limits can be configured within the system. Operators are guided through these checks, ensuring that all required tests are performed consistently and accurately. The system can also prompt operators for measurements or observations at specific intervals, preventing deviations from established quality protocols.

For instance, in an automotive parts manufacturing plant, the software might require operators to measure the torque of specific bolts at three different assembly stages, flagging any readings outside the specified range immediately.When a quality deviation or defect is detected, the software facilitates immediate root cause analysis. It can capture detailed information about the defect, including the product, batch, machine, operator, and time of occurrence.

This data is then used to identify patterns and trends, helping to pinpoint the underlying causes of quality issues. The system can also manage non-conformance reporting (NCR) workflows, initiating corrective and preventive actions (CAPA) to address identified problems and prevent their recurrence. This structured approach to quality management ensures that issues are not overlooked and that continuous improvement efforts are data-driven.

Furthermore, by maintaining a historical record of all quality data, the software provides a comprehensive audit trail, which is essential for regulatory compliance and for demonstrating a commitment to quality excellence to customers and stakeholders. The integration of quality control directly into the production workflow ensures that quality is built into the product, rather than being an afterthought, leading to fewer defects, reduced rework, and consistently higher product standards.

Real-time Data Collection and Performance Monitoring for Bottleneck Identification and Continuous Improvement

The ability to collect and analyze data in real-time is a transformative aspect of modern manufacturing management software. These systems act as a central nervous system for the factory floor, gathering critical performance indicators (KPIs) as events unfold. This continuous stream of data provides unprecedented visibility into the operational health of the plant, enabling the swift identification of bottlenecks and fostering a culture of continuous improvement.Through sensors, barcode scanners, and direct machine integration, the software captures data on machine uptime and downtime, production rates, cycle times, scrap rates, energy consumption, and labor productivity.

This information is often presented through intuitive dashboards and reports, allowing managers to see exactly what is happening on the shop floor at any given moment. For example, a dashboard might visually highlight machines that are operating below their target efficiency or lines that are experiencing frequent stoppages. This immediate insight allows for rapid intervention, preventing minor issues from escalating into major disruptions.The identification of bottlenecks is a key benefit.

Bottlenecks are points in the production process where the flow of goods is restricted, slowing down the entire operation. By analyzing real-time data on throughput and work-in-progress accumulation, the software can pinpoint these critical constraints. For instance, if the software shows a significant buildup of partially finished products before a particular assembly station, it clearly indicates that this station is a bottleneck.

Once identified, managers can focus their efforts on resolving the issue, whether it involves optimizing the process at that station, reallocating resources, or investing in new equipment.Beyond identifying immediate problems, the aggregated real-time data fuels continuous improvement initiatives. By tracking performance trends over time, manufacturers can identify areas where efficiencies can be gained, costs can be reduced, and quality can be enhanced.

This data can be used to set realistic performance targets, evaluate the effectiveness of implemented changes, and benchmark performance against industry standards. For example, a manufacturer might use historical data to identify that a specific process consistently takes longer than others, prompting an investigation into its optimization. This data-driven approach moves manufacturing from a reactive to a proactive and predictive operational model, ensuring that the company remains competitive and adaptable in a dynamic market.

Integration Capabilities with ERP and CRM for Amplified Value Proposition

The true power of manufacturing management software is often amplified when it is seamlessly integrated with other core business systems, most notably Enterprise Resource Planning (ERP) and Customer Relationship Management (CRM) platforms. This integration breaks down data silos and creates a unified, holistic view of the business, leading to a significantly enhanced overall value proposition.Integration with ERP systems is particularly crucial.

ERP software typically manages broader business functions such as finance, human resources, and procurement. When the manufacturing management software is linked to the ERP, data flows bidirectionally. For instance, production schedules and material requirements generated by the manufacturing system can automatically update inventory levels and procurement orders within the ERP. Conversely, financial data from the ERP, such as the cost of raw materials or labor, can be fed back into the manufacturing system for more accurate cost analysis and profitability tracking of specific production runs.

This ensures that financial planning is aligned with production realities, preventing discrepancies and improving the accuracy of financial reporting. It also streamlines processes like invoicing and accounts payable, as production completion can trigger these financial transactions automatically.Integration with CRM systems also brings substantial benefits. CRM platforms manage customer interactions, sales pipelines, and order management. When linked to the manufacturing system, sales teams can gain real-time visibility into production status and inventory availability.

This allows them to provide more accurate delivery estimates to customers, manage expectations effectively, and respond quickly to inquiries. If a customer requests an update on a specific order, the sales representative can access real-time production progress directly from the CRM, eliminating the need to contact the production floor and wait for manual updates. Furthermore, sales forecasts from the CRM can be used to inform production planning, ensuring that manufacturing capacity is aligned with anticipated sales demand.

This symbiotic relationship between sales and production leads to improved customer satisfaction, increased order accuracy, and a more responsive sales process. The combined insights from integrated ERP, CRM, and manufacturing management systems create a powerful ecosystem that drives efficiency, improves decision-making, and ultimately enhances the competitive edge of the organization.

Navigating the Diverse Landscape of Manufacturing Management Software Solutions for Strategic Business Alignment

Choosing the right manufacturing management software is a pivotal decision that can significantly impact a company’s operational efficiency, strategic growth, and overall competitiveness. The market offers a wide array of solutions, each with distinct architectural foundations, catering to various industry needs, offering different levels of flexibility, and presenting diverse pricing models. Understanding these nuances is crucial for making an informed choice that aligns perfectly with a business’s unique requirements and future aspirations.

This section delves into the critical aspects of evaluating these software solutions to ensure strategic business alignment.

Architectural Differences in Deployment Models

The fundamental architecture of manufacturing management software, particularly its deployment model, dictates how the system is hosted, accessed, and managed. These differences have profound implications for cost, scalability, security, and IT resource requirements. Understanding these variations is key to selecting a model that best suits an organization’s infrastructure, budget, and operational philosophy. The three primary deployment models are on-premise, cloud-based, and hybrid.On-premise solutions involve installing and running the software on a company’s own servers and IT infrastructure, located within their physical facilities.

This model offers the highest degree of control over data security, system customization, and integration with existing legacy systems. Companies retain full ownership of their data and can tailor the software precisely to their unique workflows, often through extensive custom development. However, this control comes with significant upfront investment in hardware, software licenses, and ongoing costs for maintenance, IT staff, and energy consumption.

Updates and upgrades also require internal IT resources and can be time-consuming. For organizations with strict data sovereignty requirements or highly specialized, proprietary processes, on-premise might be the preferred, albeit more resource-intensive, option.Cloud-based solutions, often referred to as Software as a Service (SaaS), host the software and data on the vendor’s servers, accessible via the internet. This model significantly reduces upfront costs as there’s no need for substantial hardware investment.

Pricing is typically subscription-based, making budgeting more predictable. Cloud solutions offer inherent scalability, allowing businesses to easily adjust their usage based on demand without significant infrastructure changes. Vendors handle maintenance, updates, and security, freeing up internal IT resources. Accessibility from any internet-connected device enhances collaboration and remote work capabilities. However, reliance on internet connectivity is critical, and customization options might be more limited compared to on-premise solutions, often relying on configuration rather than deep code changes.

Data security is managed by the vendor, which requires trust in their security protocols and compliance certifications.Hybrid models aim to combine the benefits of both on-premise and cloud deployments. This approach allows organizations to keep sensitive data or critical applications on-premise for maximum control and security, while leveraging the cloud for other functionalities like analytics, collaboration tools, or less critical operational modules.

For instance, a company might host its core ERP system on-premise but utilize a cloud-based solution for supply chain visibility or customer relationship management. This offers a balance between control, cost-effectiveness, and flexibility. Implementing and managing a hybrid environment can be more complex, requiring careful integration between on-premise and cloud components to ensure seamless data flow and consistent user experience.

It’s a strategic choice for businesses seeking to gradually migrate to the cloud or those with specific regulatory or security concerns that necessitate a mixed approach.

Key Considerations for Industry-Specific Software Selection

The manufacturing sector is incredibly diverse, with distinct operational processes and challenges across different industry verticals. Manufacturing management software must therefore be tailored to address these specific needs to deliver maximum value and drive strategic alignment. Generic solutions may fall short, leading to inefficiencies and a failure to meet critical industry demands. Understanding the core characteristics of one’s industry vertical is paramount when evaluating software options.For discrete manufacturing, which involves assembling distinct parts into finished goods (e.g., automotive, electronics, machinery), software needs to excel in areas like Bill of Materials (BOM) management, routings, work order management, and production scheduling.

Advanced capabilities in lot and serial number tracking, quality control at each assembly stage, and the ability to manage complex product configurations are crucial. Solutions often integrate tightly with Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems. The emphasis is on tracking individual units through their production lifecycle and managing a high volume of distinct product variants. Software that supports lean manufacturing principles, such as Just-In-Time (JIT) inventory and Kanban systems, is also highly valued.Process manufacturing, on the other hand, deals with formulations, recipes, and bulk materials that are mixed, blended, or transformed into finished products (e.g., chemicals, pharmaceuticals, food and beverage).

Key software requirements include precise recipe and formula management, lot traceability for regulatory compliance and recalls, co-product and by-product management, and strict quality control measures, often involving laboratory information management systems (LIMS). Batch control and real-time process monitoring are essential for consistency and yield optimization. Inventory management needs to handle bulk ingredients and finished goods with specific shelf-life considerations. Compliance with industry-specific regulations like FDA, GMP, or HACCP is non-negotiable.Mixed-mode manufacturing operations, which combine elements of both discrete and process manufacturing, present a unique set of challenges.

A company might, for example, manufacture components discretely and then use those components in a process to create a final product. Software for these environments needs to be flexible enough to handle the complexities of both assembly and formulation. This often means a platform that can manage BOMs for discrete parts and recipes for chemical or food ingredients, along with robust capabilities for managing both serialized and bulk inventory.

The ability to seamlessly transition between discrete and process workflows within the same system is a significant advantage, ensuring end-to-end visibility and control across diverse production methodologies.

Customization and Scalability Offerings from Providers

The evolving nature of business demands means that manufacturing management software must be adaptable. Different software providers offer varying degrees of customization and scalability, directly impacting a company’s ability to respond to market shifts, integrate new technologies, and grow its operations. Understanding these capabilities is crucial for ensuring long-term software viability and strategic alignment.Customization refers to the ability to modify the software to fit unique business processes and workflows that standard configurations cannot accommodate.

Some providers offer extensive customization through Application Programming Interfaces (APIs), allowing for deep integration with other systems and the development of bespoke functionalities. Others focus on configuration, where users can adjust settings, define fields, and set up rules within the existing framework without altering the core code. Highly configurable systems are generally easier to update and maintain, while deeply customized systems offer unparalleled fit but can be more complex and costly to manage and upgrade.

The level of customization required often depends on the uniqueness of a company’s operations and its competitive differentiation strategies. For instance, a company with a highly proprietary manufacturing process might require deep customization, whereas a more standard operation might thrive with a highly configurable solution.Scalability, on the other hand, is the software’s ability to grow with the business. This can manifest in several ways: handling an increasing volume of transactions, supporting more users, accommodating new product lines or facilities, and integrating with a growing ecosystem of other technologies.

Cloud-based solutions typically offer inherent scalability, as vendors manage the underlying infrastructure and can allocate resources as needed. On-premise solutions require careful planning for hardware upgrades and capacity expansion, which can be more resource-intensive. Providers that offer modular solutions also enhance scalability, allowing businesses to add new functionalities or modules as their needs evolve, rather than requiring a complete system overhaul.

When evaluating scalability, consider not just current needs but also projected growth over the next five to ten years. A solution that can scale seamlessly will prevent costly rip-and-replace scenarios down the line.

Framework for Evaluating Vendor Support, Training, and Implementation Services

The most sophisticated manufacturing management software is only as effective as its implementation and ongoing support. Vendor services play a critical role in ensuring successful adoption, maximizing ROI, and minimizing disruption. A structured framework for evaluating these services is essential to avoid common pitfalls and ensure a smooth transition.The initial implementation phase is arguably the most critical. This involves setting up the software, migrating data, configuring workflows, and testing the system.

Key considerations include the vendor’s implementation methodology – do they follow a proven, structured approach? What is their track record with similar companies and industries? Assess the qualifications and experience of the implementation team. Do they understand your industry’s nuances? What is the typical implementation timeline, and are there clear project management processes in place?

A robust implementation plan should include detailed project scope, defined roles and responsibilities, and clear go-live criteria.Vendor support encompasses the technical assistance provided after the system is live. Evaluate the availability and responsiveness of support channels (phone, email, chat). What are their Service Level Agreements (SLAs) regarding response and resolution times for different issue severities? Is support available 24/7, or only during business hours?

Understanding the vendor’s support structure and their commitment to ongoing maintenance and bug fixes is vital. Furthermore, investigate their approach to software updates and new feature releases. Are these included in the support package, and how disruptive are they?Training is paramount for user adoption and proficiency. A good vendor will offer comprehensive training programs tailored to different user roles (e.g., production planners, shop floor operators, quality control personnel).

This can include on-site training, remote sessions, online learning modules, and user documentation. The quality and accessibility of training materials are important. Are they up-to-date, easy to understand, and relevant to your specific implementation? Ongoing training opportunities for new hires or for learning advanced features are also a valuable consideration. A vendor that invests in your team’s success through effective training will significantly contribute to the software’s long-term value.

Comparative Overview of Pricing Structures and Financial Implications

The financial investment in manufacturing management software is a significant consideration, and understanding the various pricing structures is key to making a fiscally responsible decision that aligns with budget realities and long-term financial strategy. Different models have distinct upfront costs, ongoing expenses, and implications for cash flow and total cost of ownership (TCO).Perpetual licenses represent a traditional software acquisition model.

Under this structure, a company purchases a license to use the software indefinitely. This typically involves a substantial upfront cost, which can be a barrier for smaller businesses or those with limited capital. However, once purchased, there are no recurring license fees. The ongoing costs associated with perpetual licenses usually involve annual maintenance and support fees, which cover software updates, patches, and technical assistance.

For descriptions on additional topics like best hr software for startups, please visit the available best hr software for startups.

These fees are typically a percentage of the initial license cost. While offering ownership and potentially lower long-term costs if the software is used for many years without significant upgrades, the high initial outlay and the potential for costly upgrades to newer versions can be a drawback.Subscription models, prevalent in cloud-based (SaaS) solutions, involve paying a recurring fee, usually monthly or annually, for the right to use the software.

This model significantly lowers upfront costs, making it more accessible. The subscription fee typically includes software access, maintenance, updates, and often basic support. This predictable recurring expense makes budgeting easier and aligns with an operational expenditure (OpEx) rather than capital expenditure (CapEx) approach. The financial implication is a continuous outflow of funds, but it also means access to the latest features and updates without additional large upgrade costs.

Scalability is often easier with subscriptions, as you can adjust the number of users or modules based on your subscription tier, directly impacting the recurring cost.Usage-based fees, sometimes referred to as consumption-based pricing, are less common for core manufacturing management systems but can be found for specific modules or services, particularly in cloud environments. This model charges based on actual consumption of resources, such as the number of transactions processed, data storage utilized, or API calls made.

This can be highly cost-effective for businesses with highly variable workloads, as they only pay for what they use. However, it can also lead to unpredictable costs if usage fluctuates significantly or if usage patterns are not well understood. It requires robust monitoring and forecasting capabilities to manage effectively. The financial implication is a direct correlation between business activity and software cost, offering ultimate flexibility but demanding diligent oversight.

| Pricing Model | Upfront Cost | Ongoing Costs | Financial Implications | Best Suited For |

|---|---|---|---|---|

| Perpetual License | High | Annual Maintenance & Support Fees | High initial investment, predictable long-term costs if usage is stable, potential for large upgrade costs. | Large enterprises with significant capital, long-term usage plans, and desire for ownership. |

| Subscription Model | Low | Recurring Monthly/Annual Fees | Predictable operational expenses, lower barrier to entry, access to continuous updates, cost scales with usage/features. | Businesses of all sizes seeking flexibility, predictable budgeting, and access to the latest technology. |

| Usage-Based Fees | Very Low (often none) | Variable, based on consumption | Pay-as-you-go, cost directly tied to activity, can be unpredictable if usage is volatile. | Businesses with highly variable workloads or specific modular needs. |

Demonstrating the Transformative Impact of Manufacturing Management Software on Production Workflows and Workforce Productivity

Manufacturing management software, often referred to as Manufacturing Execution Systems (MES) or Enterprise Resource Planning (ERP) systems with manufacturing modules, represents a pivotal shift from manual or fragmented processes to an integrated, data-driven operational paradigm. This transformation fundamentally redefines how production unfolds, from the initial order to the final shipment, and significantly elevates the capabilities and output of the workforce.

The core of this impact lies in its ability to provide real-time visibility, streamline complex processes, and empower every level of the organization with actionable insights, ultimately leading to enhanced efficiency, reduced waste, and improved product quality.The impact of these systems on production workflows and workforce productivity is profound and multifaceted, touching upon every aspect of the manufacturing floor. By digitizing and centralizing critical operational data and processes, manufacturing management software creates a more agile, responsive, and efficient production environment.

This leads to a direct enhancement in the speed and accuracy of operations, a reduction in errors, and a more motivated and productive workforce.

Shop Floor Data Capture, Work Order Management, and Task Sequencing Mechanisms

Manufacturing management software revolutionizes shop floor operations by providing robust mechanisms for real-time data capture, sophisticated work order management, and intelligent task sequencing. These capabilities are foundational to achieving enhanced operational efficiency and improved workforce productivity. The software typically integrates with various shop floor devices, such as barcode scanners, RFID readers, sensors on machinery, and even direct machine interfaces (e.g., OPC UA), to automatically collect data points.

This includes tracking material consumption, labor time spent on specific operations, machine status (running, idle, down), production counts (good units, scrap), and quality inspection results. This eliminates manual data entry, which is prone to errors and delays, ensuring that information is accurate and immediately available.Work order management is a central pillar of these systems. Instead of relying on paper-based travelers or disparate spreadsheets, software manages the entire lifecycle of a work order.

This begins with the generation and release of production orders, which are then digitally distributed to the relevant workstations or operators. The system tracks the progress of each work order against planned schedules, highlighting any deviations or bottlenecks. It can automatically trigger the next steps in a process, ensuring that operations proceed in the correct sequence and without interruption. Task sequencing is optimized through algorithms that consider machine availability, material readiness, labor skills, and due dates.

This prevents idle time for both machines and workers, ensuring that the right task is performed at the right time by the right resource. For example, a system might automatically schedule a setup for a machine as soon as the previous job is completed and the necessary materials are staged, rather than waiting for a supervisor to manually assign the next task.

This level of control and automation ensures that production flows smoothly, minimizing lead times and maximizing throughput.

Integrated Dashboards and Reporting Tools for Informed Decision-Making

Integrated dashboards and reporting tools are the strategic nerve centers of manufacturing management software, empowering supervisors and managers with the visibility and insights needed to make timely and effective decisions. These tools transform raw operational data into easily digestible visual representations, offering a clear snapshot of the production floor’s performance in real-time. Dashboards typically display key performance indicators (KPIs) such as overall equipment effectiveness (OEE), production output against targets, scrap rates, on-time delivery performance, labor utilization, and inventory levels.

Managers can customize these dashboards to focus on the metrics most critical to their specific roles and responsibilities.For instance, a production supervisor might view a dashboard that highlights current work order status, machine downtime alerts, and the immediate availability of materials for upcoming tasks. This allows them to quickly identify and address any emerging issues on the shop floor, such as a machine unexpectedly going offline.

They can then drill down into the data to understand the root cause of the downtime, perhaps by reviewing machine logs or maintenance records directly within the software. Similarly, a plant manager might use a higher-level dashboard to track overall production efficiency trends, identify areas where performance is lagging, and assess the impact of implemented changes. Reporting tools complement dashboards by providing more in-depth analysis and historical data.

Managers can generate reports on production costs, quality trends over time, labor efficiency by department, or the effectiveness of specific production lines. These reports are invaluable for strategic planning, identifying opportunities for continuous improvement, and demonstrating performance to upper management. The ability to access this information instantly and accurately removes guesswork, enabling proactive problem-solving and data-driven strategic adjustments that directly contribute to enhanced operational efficiency.

Automation of Repetitive Tasks and Human Resource Reallocation

One of the most significant transformative impacts of manufacturing management software is its capacity to automate repetitive, manual tasks, thereby freeing up valuable human resources for more strategic and value-adding activities. Many traditional manufacturing processes involve numerous routine operations that consume considerable time and are prone to human error. Examples include manual data entry for production logs, tracking inventory movements, generating standard reports, and manually scheduling machine changeovers.

By automating these functions, the software not only increases accuracy and speed but also fundamentally redefines the roles of the workforce.When operators are no longer bogged down with tedious administrative duties, they can shift their focus to tasks that require human ingenuity, problem-solving, and critical thinking. This could involve more in-depth quality inspections, process optimization initiatives, equipment maintenance and troubleshooting, or even training newer team members.

Browse the implementation of hr system for small business in real-world situations to understand its applications.

Supervisors and managers, freed from the constant need to chase down data or manually compile reports, can dedicate more time to strategic planning, process improvement projects, employee development, and fostering a culture of innovation. For example, instead of an operator spending an hour each shift manually recording machine output and downtime, the software automatically captures this data. This allows the operator to spend that hour performing preventative maintenance checks on their assigned machinery, which can prevent future breakdowns and improve overall equipment reliability.

This reallocation of human capital is not about reducing headcount but about optimizing the utilization of skilled personnel, leading to higher job satisfaction, increased engagement, and a more dynamic and productive manufacturing operation.

Step-by-Step Procedure for Implementing a Change Management Strategy, Manufacturing management software

Implementing manufacturing management software is a significant undertaking that requires careful planning and execution, particularly concerning change management, to ensure smooth user adoption and minimize disruption. A structured approach is crucial for gaining buy-in and addressing potential resistance.The first step is to establish a dedicated change management team, comprising representatives from IT, operations, and key user groups. This team will be responsible for planning, communication, training, and support throughout the implementation process.Secondly, conduct a thorough stakeholder analysis to identify all individuals and groups affected by the new system, understanding their concerns, expectations, and potential resistance points.

This informs the communication strategy.Thirdly, develop a comprehensive communication plan. This plan should Artikel how, when, and what information will be shared with different stakeholder groups. It’s essential to clearly articulate the benefits of the new software, how it will improve their work, and what the implementation timeline looks like. Regular updates, town hall meetings, and Q&A sessions are vital.Fourthly, provide extensive and tailored training.

Training should be role-specific, practical, and delivered in a timely manner, ideally just before users are expected to interact with the system. This can include classroom sessions, hands-on workshops, e-learning modules, and job aids.Fifthly, pilot the system with a select group of users or a specific production line. This allows for real-world testing, identification of unforeseen issues, and refinement of processes and training materials before a full-scale rollout.

Feedback from the pilot group is invaluable.Sixthly, establish a robust support system. This includes providing easily accessible help desk support, super-users on the shop floor who can assist colleagues, and clear escalation procedures for technical issues.Seventhly, monitor adoption and solicit ongoing feedback. Post-implementation, it’s important to track user engagement, identify areas where users are struggling, and gather feedback for continuous improvement.

Celebrate early successes and acknowledge the efforts of the team.Finally, reinforce the changes. This involves ensuring that processes are updated to reflect the new system, that performance metrics are aligned with its capabilities, and that leadership consistently champions the use of the software.

Visual Representation of a Typical Manufacturing Workflow: Before and After Software Implementation

To illustrate the transformative impact, consider a typical discrete manufacturing workflow for assembling a custom electronic device. Before Advanced Management Software:* Order Reception: Sales receives a custom order via email or phone. Information is manually entered into a spreadsheet for tracking.

You also will receive the benefits of visiting hr management software for small business today.

Bill of Materials (BOM) and Routing

A separate team manually retrieves or creates the BOM and routing documents, often stored in shared network drives or physical binders. This process is prone to version control issues and delays.

Work Order Creation

A production planner manually creates a work order based on the BOM and routing, then prints it. This might involve checking material availability in a separate inventory system.

Material Staging

Warehouse staff manually pick materials based on a printed pick list derived from the work order. Discrepancies between the list and actual inventory can lead to delays or incorrect builds.

Assembly Line Operations

Operators receive a paper work order traveler. They manually record start and end times for each operation, note any scrap, and sign off. Machine status is often communicated verbally or via whiteboards.

Quality Control

Inspectors receive a paper inspection checklist and compare it against the finished product. Data is manually recorded.

Inventory Updates

Finished goods are manually counted and recorded in an inventory log.

Reporting

Managers spend significant time manually compiling data from various spreadsheets and logs to generate weekly production reports. After Advanced Management Software:* Order Reception: Sales enters the custom order directly into the ERP/MES system. The system automatically verifies BOM and routing validity.

Work Order Generation & Scheduling

The system automatically generates a digital work order, assigns it a priority based on due dates and production capacity, and schedules it based on machine availability and material readiness.

Digital BOM and Routing

The system provides real-time access to the correct, version-controlled BOM and routing for each work order, accessible on workstations or tablets.

Automated Material Staging

The system generates optimized pick lists for the warehouse, guiding staff with real-time inventory data. It can also trigger automatic material replenishment requests.

Real-time Shop Floor Execution

Operators access digital work orders on terminals or tablets. They scan barcodes to start/stop operations, automatically logging labor time and material consumption. Machine data is often captured directly via IoT sensors, updating status and production counts in real-time. Any scrap is immediately recorded.

Integrated Quality Control

Quality inspection steps are built into the workflow. Operators or inspectors input data directly into the system, which can flag non-conformances immediately.

Automated Inventory Management

As materials are consumed and finished goods are produced, inventory levels are updated automatically in real-time.

Instantaneous Reporting and Dashboards

Supervisors and managers have access to live dashboards displaying OEE, production progress, scrap rates, and labor efficiency. Reports can be generated on-demand, providing immediate insights for decision-making and continuous improvement.The key improvements are evident: reduced manual effort, minimized errors, real-time visibility, streamlined processes, enhanced data accuracy, and empowered decision-making, all contributing to a significantly more efficient and productive manufacturing operation.

Exploring the Future Trajectory of Manufacturing Management Software and Emerging Technological Advancements

The landscape of manufacturing management software is in a constant state of evolution, driven by rapid technological advancements. As businesses strive for greater agility, efficiency, and competitiveness, these platforms are increasingly incorporating cutting-edge technologies to address complex challenges and unlock new opportunities. The future trajectory of manufacturing management software is one of deeper integration, enhanced intelligence, and unprecedented connectivity, promising to redefine how products are designed, produced, and delivered.

Artificial Intelligence and Machine Learning for Enhanced Predictive Maintenance and Demand Forecasting

The integration of Artificial Intelligence (AI) and Machine Learning (ML) is fundamentally transforming the capabilities of manufacturing management software, particularly in the critical areas of predictive maintenance and demand forecasting. AI/ML algorithms can analyze vast datasets generated by sensors on machinery, historical production records, environmental conditions, and even external market trends. This allows for the identification of subtle patterns and anomalies that would be imperceptible to human analysis.

For predictive maintenance, ML models are trained to recognize the early signs of equipment failure. Instead of relying on scheduled maintenance, which can lead to unnecessary downtime or catastrophic breakdowns, manufacturers can now shift to a condition-based approach. For instance, an ML algorithm might detect an unusual vibration pattern in a motor, a slight increase in operating temperature, or a deviation in energy consumption, all of which could indicate an impending issue.

The software can then alert maintenance teams to inspect or repair the equipmentbefore* it fails, significantly reducing unplanned downtime, extending asset lifespan, and lowering repair costs. Companies like General Electric, through their Predix platform, have demonstrated how AI-powered analytics can predict equipment failures in industrial settings, leading to substantial savings and improved operational reliability.Similarly, AI and ML are revolutionizing demand forecasting.

Traditional forecasting methods often struggle with the volatility and complexity of modern markets. AI/ML models can process a much wider array of variables, including historical sales data, economic indicators, social media sentiment, competitor pricing, and even weather patterns, to generate more accurate demand predictions. This enhanced accuracy enables manufacturers to optimize inventory levels, reducing both the costs associated with excess stock and the risks of stockouts.

It also allows for better production scheduling, ensuring that resources are allocated efficiently to meet anticipated demand. For example, a consumer electronics manufacturer could use AI to forecast demand for a new product by analyzing pre-launch buzz on social media, early sales of similar products, and economic forecasts for the target regions. This granular forecasting allows for just-in-time production planning, minimizing waste and maximizing responsiveness to market shifts.

The ability to predict with greater precision allows for proactive decision-making across the entire value chain, from procurement of raw materials to the distribution of finished goods, ultimately boosting profitability and customer satisfaction.

The Role of the Internet of Things (IoT) in Real-Time Asset Tracking and Performance Optimization

The Internet of Things (IoT) is a cornerstone technology enabling manufacturing management software to achieve unprecedented levels of real-time visibility and control over operations. By equipping machinery, tools, inventory, and even personnel with sensors, manufacturers can generate a continuous stream of granular data about every aspect of the production process. These sensors collect information on a wide range of parameters, including temperature, pressure, vibration, location, usage status, and environmental conditions.

This data is then transmitted wirelessly to the manufacturing management software, providing a live, dynamic view of the factory floor. For real-time asset tracking, IoT devices attached to assets like forklifts, AGVs (Automated Guided Vehicles), tools, and work-in-progress (WIP) materials enable precise location monitoring. This eliminates the time wasted searching for misplaced items, improves material flow, and ensures that assets are utilized efficiently.

For example, a pharmaceutical company can track the exact location and environmental conditions of temperature-sensitive raw materials throughout the manufacturing process, ensuring product integrity and compliance with stringent regulations.Beyond simple tracking, IoT data is crucial for performance optimization. By analyzing the real-time data streams from machines, manufacturing management software can identify bottlenecks, inefficiencies, and deviations from optimal operating parameters. For instance, if a particular machine is consistently running at a slower cycle time than its programmed capacity, the software can flag this as an issue.

This might be due to a worn component, suboptimal settings, or a material handling problem. The system can then alert supervisors or maintenance personnel to investigate and rectify the issue promptly. Furthermore, IoT enables sophisticated performance monitoring and benchmarking. Key Performance Indicators (KPIs) such as Overall Equipment Effectiveness (OEE), throughput rates, and energy consumption can be monitored in real-time, allowing for immediate intervention when performance dips below targets.

Companies are using IoT to create digital twins of their assets and processes, allowing for simulation and optimization in a virtual environment before implementing changes on the physical factory floor. This data-driven approach to optimization leads to reduced waste, improved quality, increased output, and significant cost savings, making manufacturing operations more agile and responsive to market demands.

Augmented Reality (AR) and Virtual Reality (VR) for Training, Remote Assistance, and Design Visualization

Augmented Reality (AR) and Virtual Reality (VR) technologies are emerging as powerful tools within manufacturing management software, revolutionizing how training is conducted, how support is delivered, and how designs are visualized. In the realm of training, AR overlays digital information onto the real world, creating interactive and immersive learning experiences. For new employees or for complex assembly tasks, AR-guided instructions can be projected directly onto the equipment or workstation.

This allows trainees to follow step-by-step procedures, see animated demonstrations of correct techniques, and receive real-time feedback, all while working with actual machinery. This significantly reduces the learning curve, minimizes errors, and improves knowledge retention compared to traditional classroom-based training or manuals. For example, an automotive assembly line worker can use AR glasses to see the exact placement and torque specifications for each bolt they need to fasten, ensuring consistency and accuracy.Remote assistance is another area where AR is making a significant impact.

When a technician encounters a complex problem on the factory floor, they can use AR to connect with an expert located elsewhere. The expert can see exactly what the technician sees through their AR device and can then provide real-time visual guidance, annotating the technician’s view with instructions, diagrams, or highlighting specific components. This reduces the need for costly and time-consuming on-site visits by specialists, speeding up problem resolution and minimizing downtime.

Companies like Boeing have utilized AR for complex wiring tasks, allowing technicians to accurately route cables with visual overlays, dramatically reducing assembly time and errors. VR, on the other hand, creates fully immersive digital environments. This is invaluable for design visualization and simulation. Engineers can walk through a 3D model of a new factory layout or product design, identifying potential clashes, ergonomic issues, or manufacturing challenges before any physical prototypes are built.

This iterative design process in VR can save immense amounts of time and resources. Furthermore, VR can be used for complex simulations, such as training operators on how to manage a critical failure scenario in a safe, virtual environment, preparing them for real-world emergencies without any risk.

The Evolving Importance of Cybersecurity Measures and Data Privacy within Sophisticated Manufacturing Management Platforms

As manufacturing management software becomes more interconnected and data-intensive, the importance of robust cybersecurity measures and stringent data privacy protocols cannot be overstated. These platforms are the central nervous system of modern manufacturing operations, managing everything from intellectual property and production schedules to sensitive financial data and employee information. A breach in cybersecurity can have catastrophic consequences, including production shutdowns, theft of trade secrets, financial losses, reputational damage, and even physical safety risks if critical infrastructure is compromised.

Therefore, sophisticated manufacturing management platforms are increasingly incorporating multi-layered security defenses. These include advanced access controls, role-based permissions to ensure that users only have access to the data and functionalities they need, and regular security audits and vulnerability assessments. Encryption of data both in transit and at rest is a fundamental requirement, protecting sensitive information from unauthorized access even if it is intercepted.Data privacy is intrinsically linked to cybersecurity, especially with the growing volume of personal data that may be collected and processed within these systems, such as employee performance data or visitor logs.

Compliance with global data protection regulations like GDPR (General Data Protection Regulation) and CCPA (California Consumer Privacy Act) is paramount. Manufacturing management software must be designed with privacy-by-design principles, ensuring that data collection is minimized, consent is obtained where necessary, and data subject rights are respected. This involves clear data retention policies, mechanisms for data anonymization or pseudonymization, and secure methods for data deletion.

Furthermore, as manufacturers adopt more cloud-based solutions and connect with external partners, the attack surface expands. This necessitates secure API management, secure integration protocols, and thorough vetting of third-party vendors to ensure they also adhere to high security and privacy standards. The ongoing evolution of cyber threats means that cybersecurity and data privacy are not static concerns but require continuous monitoring, adaptation, and investment to protect the integrity and confidentiality of manufacturing operations and sensitive data.

The Potential for Blockchain Technology to Enhance Supply Chain Transparency and Traceability in Manufacturing Operations

Blockchain technology holds significant potential to revolutionize supply chain transparency and traceability within manufacturing operations, addressing long-standing challenges of trust, visibility, and accountability. At its core, a blockchain is a distributed, immutable ledger that records transactions across a network of computers. Each transaction, once verified, is added as a “block” to the chain, linked cryptographically to the previous block, creating a tamper-proof record.

In the context of manufacturing supply chains, this means that every step of a product’s journey, from the sourcing of raw materials to its delivery to the end consumer, can be recorded on a blockchain. This creates an unprecedented level of transparency, as authorized participants in the supply chain can access this shared ledger to view the provenance and movement of goods in near real-time.

For instance, a manufacturer of high-value electronics could use blockchain to track the origin of every component, ensuring that ethically sourced materials are used and that counterfeit parts are prevented from entering the production line.Traceability is greatly enhanced by blockchain because each transaction is time-stamped and immutable, making it easy to pinpoint the exact location and status of a product at any given moment.

This is invaluable for quality control and recall management. If a defect is discovered in a batch of products, the manufacturer can quickly and accurately identify all affected items and their distribution, enabling targeted recalls and minimizing broader impact. Furthermore, blockchain can facilitate more efficient and secure payment processes within the supply chain through smart contracts. These are self-executing contracts with the terms of the agreement directly written into code.

Once predefined conditions are met (e.g., goods are received and verified), the smart contract automatically triggers a payment, reducing delays and disputes. Companies like Walmart have explored blockchain for food traceability, enabling them to track produce from farm to store in seconds rather than days, significantly improving food safety and reducing waste. The inherent security and transparency of blockchain technology can foster greater trust among supply chain partners, streamline operations, and ultimately build more resilient and responsible manufacturing ecosystems.

Final Thoughts

In essence, manufacturing management software is not merely a tool but a strategic imperative for modern manufacturers. From optimizing daily operations and ensuring product quality to fostering innovation and adapting to future technological shifts, these systems empower businesses to achieve unparalleled levels of efficiency, agility, and competitiveness. Embracing these solutions is a critical step towards navigating the complexities of today’s industrial landscape and securing a prosperous future.

Quick FAQs: Manufacturing Management Software

What is the primary benefit of implementing manufacturing management software?

The primary benefit is enhanced operational efficiency through streamlined planning, scheduling, resource allocation, and real-time data monitoring, leading to reduced waste and improved productivity.

Can manufacturing management software be customized to fit unique business processes?

Yes, many software providers offer varying levels of customization and scalability to meet specific industry verticals and evolving business needs, though the extent can differ significantly between solutions.

How does manufacturing management software impact inventory levels?

It significantly improves inventory control and materials management by optimizing stock levels, reducing waste, and ensuring the right materials are available at the right time, thus preventing stockouts and overstocking.

What role does quality control play in manufacturing management software?

Quality control modules within the software contribute to defect reduction by enabling consistent monitoring of production processes, enforcing quality standards, and facilitating timely identification and correction of issues.

Is training and support crucial for successful adoption of this software?

Absolutely. Evaluating vendor support, training programs, and implementation services is a critical consideration to ensure smooth user adoption and maximize the return on investment.